Green Hydrogen

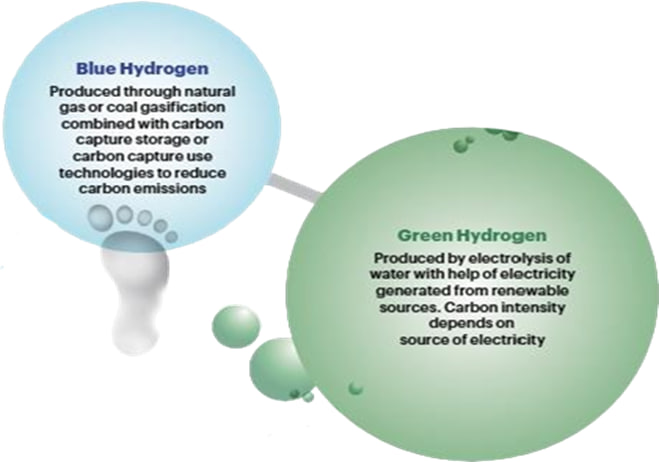

Although hydrogen is one of the most abundant elements on earth, in its pure form it is rare. Extracting hydrogen from its compounds requires a lot of energy. Although these energy sources can be diverse, the most popular hydrogen production method is carbon dioxide intensive. Most of the world’s hydrogen production consists of “grey hydrogen,” produced via steam methane reforming (SMR), which forms both hydrogen and carbon dioxide. In contrast, the term “blue hydrogen” is reserved for hydrogen production that involves carbon capture and usage or the storage of emitted carbon dioxide. Additionally, the electricity intensive electrolysis of water is yet another process for producing hydrogen and is the only carbon-neutral technique (provided that renewable energy sources can be used); this is known as “green hydrogen.”

There are generally two ways to use (green) hydrogen in steel production. First, it can be used as an alternative injection material to PCI, to improve the performance of conventional blast furnaces. Although the use of PCI is common, the first pilot plants using hydrogen injection have recently been set up to assess decarbonization potential. However, while the injection of (green) hydrogen into blast furnaces can reduce carbon emissions by up to 20 percent, this does not offer carbon-neutral steel production because regular coking coal is still a necessary reductant agent in the blast furnace.

Second, hydrogen can be used as an alternative reductant to produce DRI that can be further processed into steel using an EAF. This DRI/EAF route is a proven production process that is currently applied using natural gas as a reductant, with access to a cheap natural gas supply. However, the direct reduction process can also be performed with hydrogen. Based on the use of green hydrogen as well as renewable electricity from wind, solar, or water, a DRI/EAF setup enables nearly carbon-neutral steel production.

In more detail, a large-scale, green hydrogen-based DRI/EAF steel production process involves the following core process steps:

1. Green hydrogen production. Green hydrogen is produced by electrolyzing water in a process that requires significant amounts of electricity. Obtaining sufficient electricity from renewable energy sources will be the key challenge for green hydrogen production.

2. DRI production. In the DRI plant, iron ore in the form of DR pellets8 is reduced with hydrogen in order to form DRI.9 Using hydrogen as the reductant releases only water (i.e., it does not produce carbon emissions).

3. Raw steel production using an EAF. In the EAF, the DRI is heated and liquified together with steel scrap to produce raw steel. The use of electricity in this process (assuming it is from renewable sources) does not lead to any carbon emissions.

The Green Hurdle

Managing the transition from fossil fuels to hydrogen without hurting the country’s economic momentum is a challenge in itself. Pricing will be key as capturing and transporting hydrogen is expensive.

Scientists have been exploring the possibility of using hydrogen to produce energy for decades as it is an abundant element. There are three types of hydrogen. ‘Grey hydrogen’, produced from coal/lignite gasification or steam methane reformation (methane from natural gas is heated with steam to produce carbon monoxide and hydrogen). ‘Blue hydrogen’ is produced from natural gas or coal gasification. Both pollute the air one more, one less than the other. The only net zero fuel is ‘green hydrogen’, which burns cleanly, releasing only water vapour.

However, today, the cost of splitting water to generate green hydrogen is more than the value of energy produced. Current production cost of green hydrogen, $3-6 per kg, has to come down to under $2-2.5 per kg to make it viable. “India can bring down the cost of hydrogen to $1 per kg. This will make it the first to reach $1 per one kg in one decade the 1-1-1 target”.

IEA says it’s possible to reach $1.3-4.5 per kg as cost of producing renewable energy falls and electrolysers become 70% cheaper by 2030. Electrolysers split water into hydrogen and oxygen. A report by Institute For Energy Economics And Financial Analysis (IEEFA)says. electrolyser costs must fall below $250 per megawatt from $700-1,000 and renewable energy from $30-35 per megawatt hour to $20 for green hydrogen to become viable.

Hydrogen For Mobility

Experts say large scale transition to hydrogen will start with HFC-powered automobiles and ships.

WHY HYDROGEN

• It will replace fossil fuels as source of clean energy.

• Green hydrogen can help India meet net-zero ambition since it bums clean leaving only water vapour behind.

• 5 MMT green hydrogen per year can reduce fossil fuel imports by (Rs. l lakh crore greenhouse) gas emissions by 50 MMT.

• Green ammonia and hydrogen can reduce LNG import bill and help reduce fertiliser subsidy bill of nearly Rs.1 lakh crore.

PRICING CHALLENGES

• With existing technologies, the cost of splitting water to get green hydrogen is more than the value of energy produced

• Production cost is $5-6/kg. Need to bring it below $2-2.5/kg.

• To compete with grey hydrogen at $2/kg, cost of two main inputs electrolysers and renewable energy, must decline. Electrolysers must fall from $700-1,000 to below $250/MW and renewable energy from $30-35 per MWh to $20 per MWh.

This is an example page. It’s different from a blog post because it will stay in one place and will show up in your site navigation (in most themes). Most people start with an About page that introduces them to potential site visitors. It might say something like this:

Hi there! I’m a bike messenger by day, aspiring actor by night, and this is my website. I live in Los Angeles, have a great dog named Jack, and I like piña coladas. (And gettin’ caught in the rain.)

…or something like this:

The XYZ Doohickey Company was founded in 1971, and has been providing quality doohickeys to the public ever since. Located in Gotham City, XYZ employs over 2,000 people and does all kinds of awesome things for the Gotham community.

As a new WordPress user, you should go to your dashboard to delete this page and create new pages for your content. Have fun!